One More Custom Bike

The last full custom bicycle of the year has just been completed and rolls out of the store with its new owner. Anyone visiting the store over the last few months has probably seen parts of this build laying around the workshop and the frame had been hanging on a hook for longer than usual. Everything about this bike has been meticulously planned and built to create the perfect bike for the rider. A few teething problems along the way, as with all custom builds, however the end result, though slow in coming, has been worth the wait.

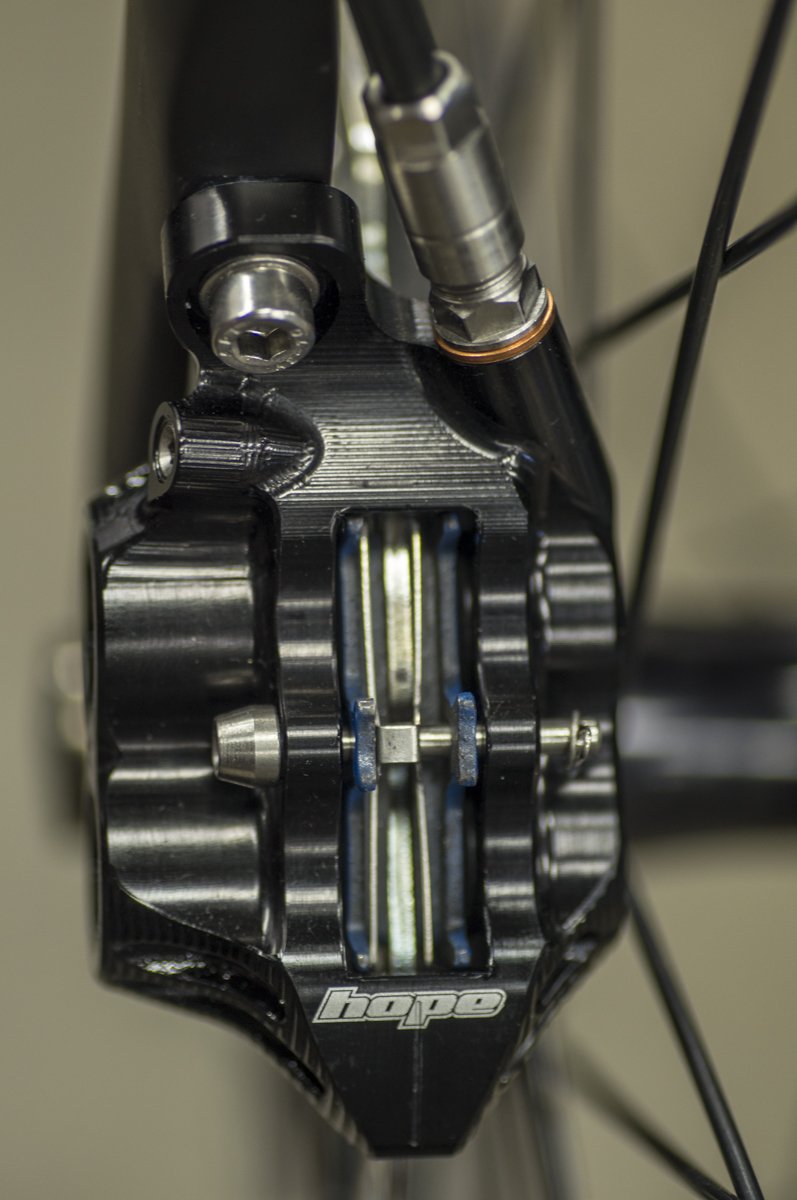

The frame is a full custom design, built around the riders’ measurements and the geometry set for his personal style and intended use, in this case the design is for a very quick handling, light gravel bike. The frame is built in Titanium and was built by master frame builder Mike DeSalvo in Oregon. The wheels are hand built by myself using DT Swiss rims and modified hubs from White Industries. The shifting is by a cable actuated traditional setup but the brakes are hydraulic. Whilst on the subject of brakes, one of the biggest features on this bike is the braking system. The calipers are from Hope in England and are completely machined from one single piece of aluminum, obviously being from England they used Alumin(i)um… Despite the spelling this is a very complex caliper. Designed for use with a road bike lever they are small in size and lightweight but have fantastic stopping power but still maintain good feel and modulation at the lever. The calipers actually have 4 pistons and need a good amount of fluid, the hose was originally a braided stainless, specially designed to be used with these calipers, unfortunately we had a few problems with it and eventually a failure in the casing itself. At the moment we are using Shimano high flow hose but eventually we will switch to braided high flow hose from Jagwire. We just need to customize the fittings for the caliper end and the lever end to suit. The rotors are also from Hope and are their floating design that have been around for a while now. I will do a separate post on the reason behind this design of rotor at a later date.

Wheels are setup to run tubeless and are running a 700 x 30 tire. The wheels have been laced using spoke washers at the hub and rim washers in rim along with the DT Swiss pro head nipples. Tension is maxed out on these rims obviously and the 32 spokes are laced in a 3 x pattern. As much as I love DT Swiss rims, spokes and hubs, I am not a big fan of their tubeless rim tape so I opted instead for Whiskey brand tape. I also departed from the usual sealants and went instead to Finish Line. Should have a little longer before it dries.

Running a standard 50/34 chain ring combo however, we have gone to our favorite brand for rings, Praxis. This is their “Zayante” model. The derailleurs front and rear are standard Shimano units although you may be unfamiliar with the newer shape and, especially the cable routing on the front. The rear is a Shadow model and shares some characteristics with standard road and some mountain bike models. Ideal for this gravel application. These new models have fantastic chain wrap and engagement. Rear dropout is thru-axle and the less common Syntace style.

So, there it is, another full custom framed rig. This bike has been in the workshop for so long I miss it now that it is gone. The owner is local so I will get to visit with it and if you are riding around the area keep your eye out for a glimpse, but you won’t catch it… Michael is too quick.